OEM/ODM China High Conductivity Silver Wire Enameled1 Silver Plated Enameled Copper Wire – Tianchuang

OEM/ODM China High Conductivity Silver Wire Enameled1 Silver Plated Enameled Copper Wire – Tianchuang Detail:

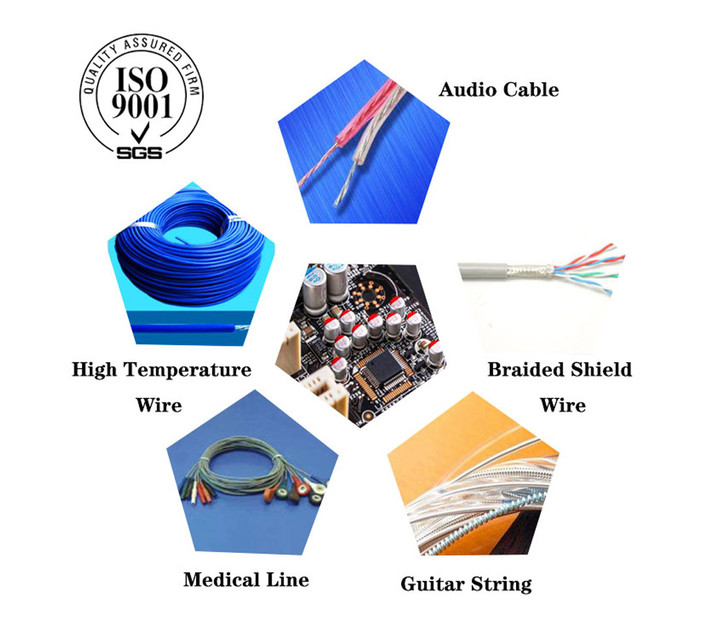

Shanghai Tianchuang Cable Technology Development Co., Ltd. was founded in 2007, the company specializing in the production of metallic conductor.Our company has been concentrating on the brand management and the development of the innovation of product technology. Our company has obtained the ISO9001 quality management system certification.Now we provide various kinds of special wire material for the industries in terms of internal aviation and spaceflight,electron information and military industry and some branch production,etc.We played a very important role in our national important projects,the establishment of national defense and international engineering.

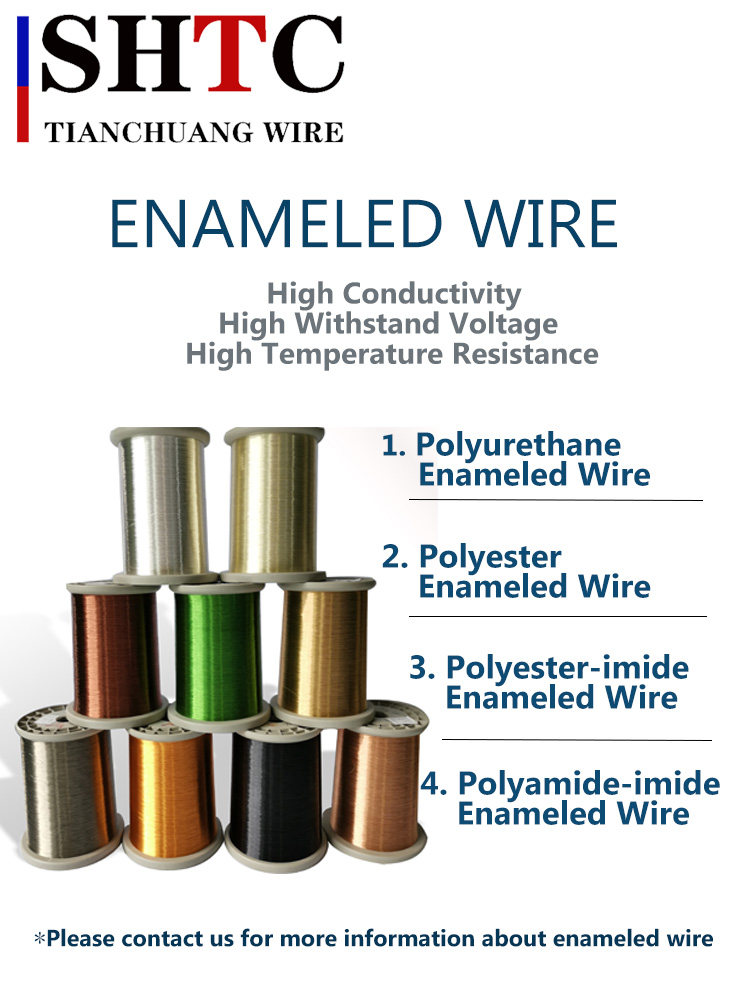

Type of Insulation

| Insulation-enameled Name | Thermal Level⁰C(working time 2000 h) | Code Name | GB Code | ANSI.TYPE |

| Polyurethane enameled wire | 130 | UEW | QA | MW75C |

| Polyester enameled wire | 155 | PEW | QZ | MW5C |

| Polyester-imide enameled wire | 180 | EIW | QZY | MW30C |

| Polyester-imide and polyamide-imide double coated enameled | 200 | EIWH(DFWF) | QZY/XY | MW35C |

| Polyamide-imide enameled wire | 220 | AIW | QXY | MW81C |

Specification

| Model | Diameter(mm) |

| 0.05-3.83 |

Materials and product standards

| Copper Wire | GB/T3953 |

| Silver | GB/4135 |

| Silver-plated Soft Found Copper Wire | JB/T3135 or ASTM B298-99 |

Resistivity

| Not more than 0.017241 | Ω.m ㎡/m, at 20℃,Resistance temperature coefficient 0.00391/℃ |

Dimensions and Deviations

| Diameter standard (mm) | Deviation |

| 0.110-0.250 | ±0.005 |

| 0.251-0.700 | ±0.010 |

| 0.710-1.0 | ±0.015 |

| 1.100-3.83 | ±0.020 |

Mechanical Behavior

| Diameter standard (mm) | Partial tensile strength not less than | Elongation not lower than |

| 0.05-0.100 | ———— | 5.5 |

| 0.11-0.15 | 196 | 10 |

| 0.151-0.250 | 196 | 15 |

| 0.251-0.700 | 196 | 20 |

| 0.710-1.000 | 196 | 25 |

| 1.100-3.83 | 196 | 25 |

Product Details

Product Processes

Enameled wire is a major type of winding wire, which consists of conductor and insulating layer. The bare wire is tempered and softened, then painted for many times and baked. However, it is not easy to produce products that meet both the standard requirements and customer requirements. It is affected by factors such as raw material quality, process parameters, production equipment, environment, etc. Therefore, the quality characteristics of various enameled wire are different, but they all have four major properties: mechanical properties, chemical properties, electrical properties and thermal properties.

Packing and delivery

1.The mono-filament and its winch are supplied in plates, and then packed and delivered in boxes after proper packaging with Kraft paper and packaging film. The small size disc is fixed by custom foam, and the large size plastic rubber disk or iron disk is fixed by custom wooden frame.

2.The mono-filament and its strand are evenly wound on the wire shaft, the wire arrangement is not pressed, the wire head is fixed, and the outermost side of the wire is kept at a certain distance from the edge of the disk, so as to avoid collision in the course of transportation.

The Application Field of Products

Enameled wire is the main and key raw material for electric motors, electrical appliances and household appliances, telecommunications and electronic instrument electromagnetic winding. After joining WTO, with the rapid development of industrial appliances, household appliances, telecommunications, electronic products, etc. It has brought enameled wire a broader application field and market.

Exhibition and Certification

FAQ

Q1: What are your prices?

A1: Our prices are subject to change depending on supply and other market factors.

Q2: What is the product warranty?

A2: We warranty our materials and workmanship. Our commitment is to your satisfaction with our products.

Q3: What kinds of payment methods do you accept?

A3: You can make the payment to our bank account, Western Union or PayPal: 30% deposit in advance, 70% balance against the copy of B/L.

Q4: What is the average lead time?

A4: For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

Product detail pictures:

Related Product Guide:

No matter new customer or outdated client, We believe in extensive phrase and trusted relationship for OEM/ODM China High Conductivity Silver Wire Enameled1 Silver Plated Enameled Copper Wire – Tianchuang, The product will supply to all over the world, such as: Munich , Jakarta , Bulgaria , Further, we are supported by highly experienced and knowledgeable professionals, who have immense expertise in their respective domain. These professionals work in close coordination with each other to offer our clients an effective range of products.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.