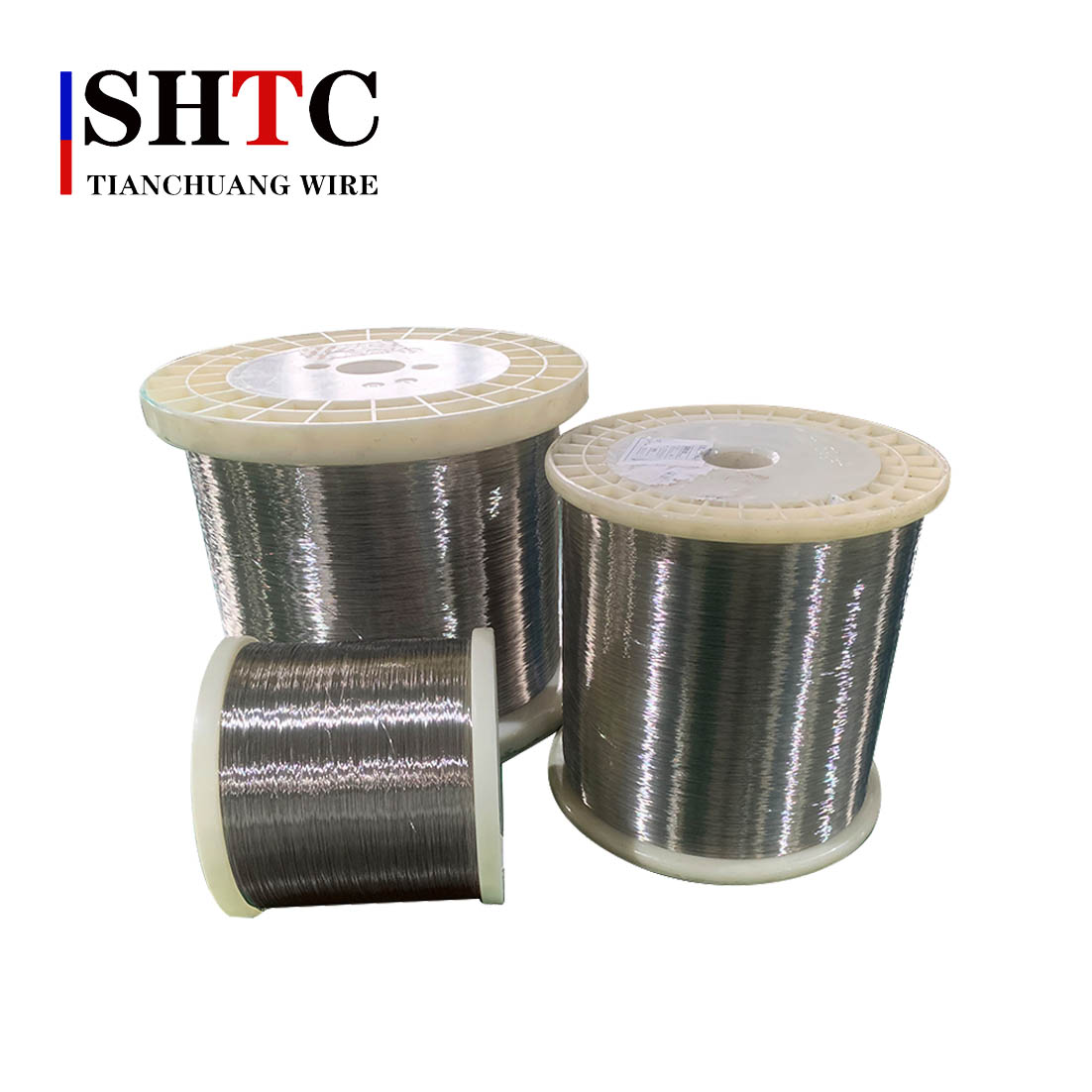

NICKEL PLATED COPPER WIRE

Operating electronics under harsh conditions like extreme heat could potentially do harm to the overall device. Protecting the wires of these devices is utterly necessary. If you need copper wires in hot conditions, consider plating the wire with nickel. Without nickel, copper will most likely oxidize. Oxidation is hard to see with the naked eye, but the damage is still happening to the wires and the device. Protecting wires with a thermal resistance substance like nickel, tin, or silver will help to extend the life of cables while also preventing damages.

Shanghai Tianchuang nickel plated copper wire is composed of a copper core, covered by a concentric nickel plating. Pure electrolytic copper wire uniformly electroplated with nickel. Nickel plating is applied to wire products due to its excellent corrosion resistance properties and in particular, its durability and stability at extremes of temperatures.

Shanghai Tianchuang nickel plated copper wire is available in diameters from 0.08mm to 1.13mm (AWG 40 - 17) with all insulation and self-bonding enamels as well as bare nickel plated copper wires.

Nickel is used over tin because tin can only be heated to temperatures around 150 degrees Celsius. Both silver and nickel can be used at temperatures above 200 degrees Celsius, but nickel is less expensive and more practical to use. Nickel also provides unmatched resistance to corrosion, which allows them to be durable and stable at high temperatures. Standard plating uses roughly 27% nickel on the copper wire. Nickel-plated copper wires can work in extreme conditions up to 750 degree Celsius.

There are other benefits of purchasing and using nickel-plated copper wires; such are easy welding for lead wires. If you need more information about these wires and how they might benefit you and your company, reach out for more details today.

Post time: Jun-24-2020